In 2020, 1,076 engineering, consulting, EPC and construction projects were implemented in China, 929 projects were newly commenced and 550 projects achieved mechanical completion.

Continuous Improvement of Engineering Service

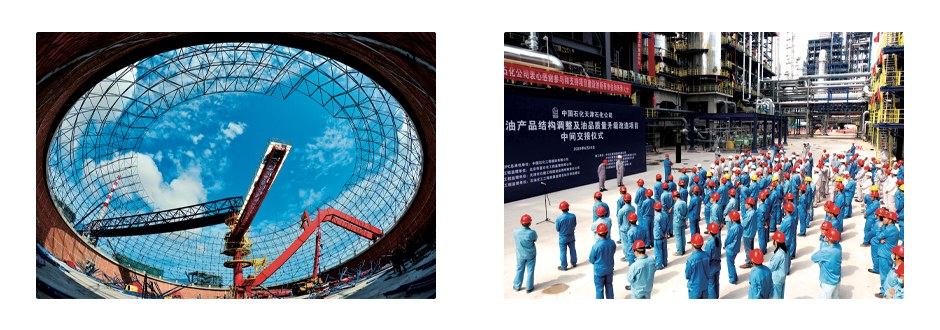

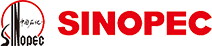

We strengthened whole process management and took multiple measures simultaneously to enhance engineering design efficiency and project execution level. Refining structural adjustment projects in Sinopec Zhongke, Sinopec Tianjin and Sinopec Luoyang were started up in full swing. Commercial crude oil storage projects in Tianjin, Kuche and Zhanjiang, residue hydrotreating project in Maoming and EVA project in Yangzi achieved mechanical completion after being constructed at an ultra-conventional pace. We also progressed with projects such as SSTPC polycarbonate, ZRCC base and Gulei refining and petrochemical integration. Sinopec Hainan ethylene, Sinopec Anqing structural adjustment and Sinopec Baling caprolactam projects with project safety and quality under control.

We increased the input of automatic welding machines, increased the proportion of pipeline prefabrication, and constantly improved the project management. We continuously enhanced information technology application with digital delivery of major projects in Gulei, Hainan and ZRCC progressing smoothly. While continuously providing customers with high-quality services in the traditional petrochemical industry, the Company also provided customers with overall solutions in the fields of new coal chemical industry, LNG, bio-energy, soil treatment etc, and gradually realized transformation from a single engineering contractor to a comprehensive service provider covering the whole energy and chemical industrial chain and full life circle.

Key Technological Innovation Projects Completed

22 key R&D projects were well under way. 8 projects including 2nd generation of high-efficiency and environmentalfriendly aromatics technology and solid super acid C5 and C6 isomerization technology industrial test were completed at high standards. 8 projects including development and industrial application of complete technology for producing ethylene directly from crude oil were added to the research list.

Projects such as the catalytic cracking and hydro desulfurization of TSRMP and low sulfur fuel oil components were mechanically completed on schedule. A batch of projects entered normal operation stage such as the complete technology of 400,000 tonnes per year kta low cost ethane cracking gas to styrene, purification and supply technology R&D for hydrogen used for fuel cell vehicles, and standards for oil-hydrogen combined service stations as well as the construction and application of related supply chain.

Address

Address Post code

Post code Tel

Tel

川公網安備11000132213211

川公網安備11000132213211