Sinopec deeply implemented the Innovation-Driven Development Strategy, adhered to the "Four faces", focused on the construction of industrial pattern of “one foundation, two wings, and three new growth points”, and pushed forward the overall planning of "Four Batches" for sci-tech innovation. Furthermore, it accelerated technological breakthroughs in industrialization, strengthened major ground-breaking basic research efforts, intensified reforms of science and technology systems and mechanisms, and promoted intelligent upgrades to the entire industrial chain, thus adding strong momentum to the high-quality development of the company.

Strengthened sci-tech innovation

System and mechanism management of sci-tech innovation

With eight directly affiliated research institutes, two overseas research and development institutions, and more than 50 enterprise-affiliated research institutions, Sinopec established 25 national research and development institutions, and 36 key laboratories of the group companies. Four technology platforms, including oil and gas exploration and development, petroleum refining, petrochemical engineering and safety, and environmental protection public technology had been established. In 2020, Sinopec established a long-term mechanism for the continuous growth of science and technology investment, and deepened the reform of "streamlining administration and delegating power, improving regulation, and upgrading services" in the science and technology field. Moreover, it launched the "technological reform demonstration initiative", and pushed forward the establishment of new research and development institutions and scientific and technological incubators. Therefore, it created a sound innovation ecosystem and motivated the vitality of sci-tech innovation.

Scientific and technological talent team building

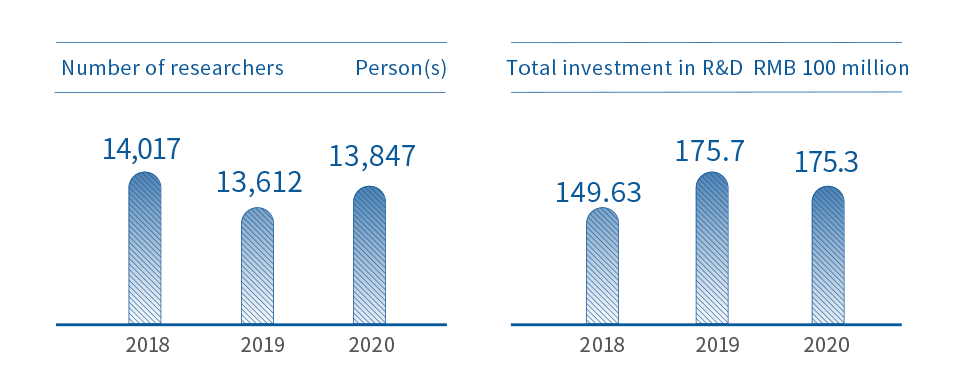

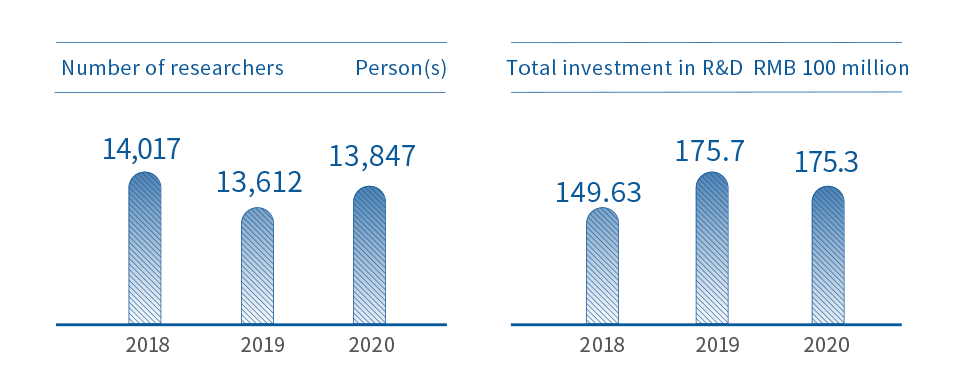

Firmly holding the concept that "talented personnel are the primary resources", Sinopec vigorously implemented a strategy to strengthen the company through acquisition and retention of talented personnel to constantly build a more powerful scientific and technological talent team. Relying on sci-tech innovation platforms of major scientific research and engineering projects as well as key laboratories of the state and the group companies, Sinopec reinforced the cultivation of leading talents in science and technology. The Youth Innovation Fund was set up and outstanding Youth Innovation Fund topics were selected to strengthen the cultivation of young sci-tech personnel. The technical reward incentive mechanism was implemented to further strengthen rewards for science and technology. For example, innovation teams were selected, and the incentives for sci-tech innovation were increased. The spirit of scientists was vigorously promoted to increase the sense of mission and responsibility of researchers to overcome difficulties and pursue innovation. In 2020, two persons were awarded the "Scientific and Technological Innovation Award", and eight persons as the "Outstanding Young Scientific and Technological Innovation Talent".

Transformation and application of sci-tech innovation achievements

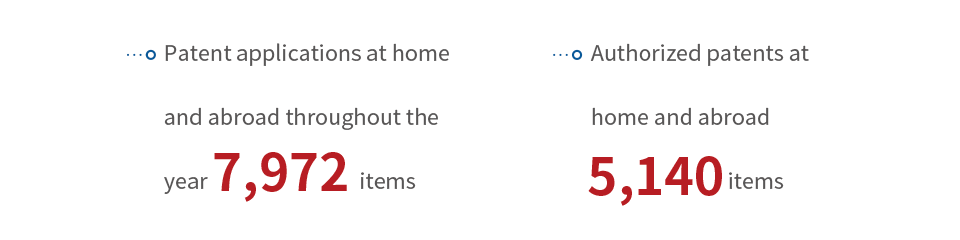

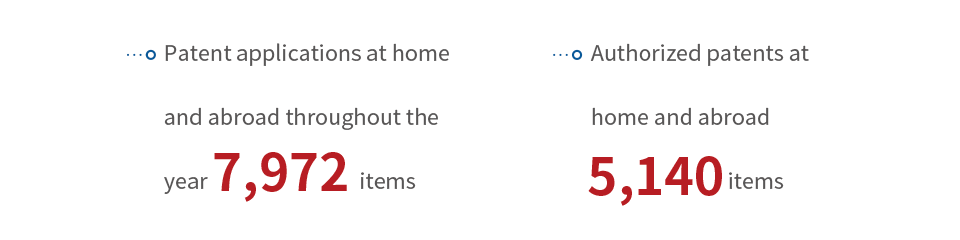

In 2020, the Company obtained a number of major scientific and technological achievements, and its patent comprehensive advantage ranked at the top among central SOEs. Of the 7,972 patents applied for at home and abroad throughout the year, 5,140 were approved. It obtained one China Patent Gold Award, three China Patent Silver Awards and six China Patent Excellence Awards.

With respect to oil and gas exploration and development technology, shale oil and gas exploration theory and technology made new breakthroughs, and the first domestic atmospheric shale gas resource section was found. Key technology and equipment of ultra-deep petroleum engineering made a breakthrough. A seismic node acquisition system was developed and applied on a large scale. With respect to refining technology, production technology of low carbon olefins by fast catalytic pyrolysis, and packaged technology of high slagging low emission heavy oil catalytic cracking realized industrial transformation. With respect to chemical and material technology, packaged technology of 48 K large tow carbon fiber was developed to realize the industrial production of series of biodegradable materials such as PBST, and production technology of medical and health raw materials such as melt-blown material (cloth) was rapidly overcome. With respect to public technologies, zero discharge of high salt wastewater from coal chemical industry, as well as high flux plasma to treat VOCs achieved industrial application.

The new generation DOT-300 catalyst developed by Sinopec Shanghai Research Institute of Petrochemical Technology was subject to industrial tests by Sinopec Maoming Petrochemical Company, and successfully achieved technical calibration, marking the successful industrial application of a new generation high activity and long-lived deolefin catalyst. This will greatly reduce the cost of aromatic deolefin processing and the amount of hazardous solid waste such as deactivated clay, which is important to reduce costs and increase the efficiency of the aromatic hydrocarbon industry.

As a project leader, Sinopec Beijing Research Institute of Chemical Industry cooperated with 16 units, including Sinopec Tianjin Petrochemical Company, Sinopec Yanshan Petrochemical Company, Sinopec Zhenhai Refining & Chemical Company, and developed a series of functional films and becoming a global leader after just three years worth of research. In June, the major scientific and technological project of Sinopec, i.e. "key technologies of functional polymer film materials", passed appraisal.

Promoted "integration of industrialization and digitization"

Guided by a new vision of development, Sinopec vigorously promoted industrial and digital transformation. Based on the new model of "data+platform+application", it continued to strengthen the integration of information and digital technologies with industrial entities to create new advantages in industrial competition. Therefore, it constantly drove new energy to build a world-leading clean energy chemical company and to lead the high-quality development of China's energy and chemical industry.

Upgraded smart plant, and empowered high quality development by digital transformation

Taking petrochemicals as a starting point, Sinopec promoted industry-wide intelligent manufacturing step-by-step to push forward the transformation of the company to be visualized, integrated, digitized and intelligent. Based on early pilot studies, Sinopec continued to upgrade its smart plant. Based on the technical architecture of the industrial Internet platform, Sinopec promoted smart plant 2.0 and studied smart plant 3.0 to reinforce the optimization and integration of information system in the aspects of technology, management, operation, marketing, and others. In 2020, six companies, including Qilu Petrochemical, Qilu Petrochemical and Shanghai Petrochemical, finished the promotion and construction of smart plant 2.0. ZRPC realized synchronous design, synchronous construction, and synchronous commissioning of production base and smart plant for the first time. As of 2020, Sinopec had constructed a total of 11 smart refinery plants.

Pushed forward the establishment of "SINOPEC Chememall Global", and continued to create the new business form of "Internet+"

Sinopec actively promoted the application of "SINOPEC Chememall Global" chemicals e-commerce platform to achieve rapid development, which had become the e-commerce platform with the largest turnover of petrochemical products in the industry. In 2020, focusing on institutional reform under the mode of e-commerce chemical sales, and cooperating with chemical sales, Sinopec realized the adjustment of post authorities of 42 major business processes, adjusting the workflow and approval process of sales planning and sales order, as well as the adjustment of distribution fee management. Furthermore, it launched the application online for the companies in north China, east China, south China, central China, and other regions. Through deepening the application of e-commerce services, Sinopec finished 97 newly added functions and 89 functional optimizations, covering the areas of sales separdined bill and proprietary procurement, which improved business processing efficiency as well as management and control ability. Moreover, Sinopec continued to optimize key business processes such as planning, orders, and payment, so as to improve user experience and continuously expand online sales. There were more than 11,000 member clients, including more than 5,400 active clients. The sales volume eclipsed 55 million tons.

Address

Address Post code

Post code Tel

Tel 川公網安備11000132213211

川公網安備11000132213211